Ultrasonic Testing for Pipeline Inspection in Egypt: A Groundbreaking Approach

Ultrasonic testing for pipeline inspection is a critical method for ensuring the safety and integrity of pipelines. In Egypt, the use of ultrasonic testing for pipeline inspection has seen a groundbreaking approach in recent years. With the growing importance of pipeline infrastructure in Egypt, the need for advanced and reliable inspection techniques has become paramount. This paper discusses the innovative use of ultrasonic testing for pipeline inspection in Egypt and the significant impact it has had on the country's pipeline industry.

Ultrasonic Testing for Pipeline Inspection in Egypt: A Groundbreaking Approach is a comprehensive study on the use of ultrasonic testing technology for inspecting pipelines in Egypt. The approach utilizes advanced ultrasonic techniques to detect and diagnose defects such as corrosion, cracks, and weld imperfections in pipelines. The study discusses the benefits and challenges of implementing this innovative approach in the Egyptian pipeline industry, along with practical recommendations for its successful application. Additionally, it highlights the potential cost savings and increased safety that can be achieved through the adoption of ultrasonic testing for pipeline inspection in Egypt.

The Importance of Ultrasonic Testing for Pipeline Inspection in Egypt

In Egypt, the use of ultrasonic testing for pipeline inspection has become increasingly vital in ensuring the safety and integrity of the country's pipeline infrastructure. This non-destructive testing method allows for the detection of flaws, corrosion, and other potential issues within pipelines, helping to prevent costly and potentially dangerous incidents. By employing advanced technology and adhering to best practices, Egypt can continue to improve the effectiveness and reliability of ultrasonic testing for pipeline inspection.

Ultrasonic testing is crucial for the inspection of pipelines in Egypt due to the country's extensive infrastructure of oil and gas pipelines. This non-destructive testing method allows for the detection of internal flaws, corrosion, and wall thickness measurements, all of which are essential for ensuring the integrity and safety of the pipelines. With the high demand for oil and gas in Egypt, maintaining the reliability of the pipeline network is of utmost importance. Ultrasonic testing plays a vital role in preventing potentially catastrophic failures and ensuring the continuous and safe operation of the pipelines. Furthermore, it helps in complying with the stringent regulations and standards set by the Egyptian government and international bodies. Overall, the importance of ultrasonic testing for pipeline inspection in Egypt cannot be overstated, as it directly contributes to the country's energy security and economic stability.

Benefits of Implementing Ultrasonic Testing in Egyptian Pipeline Inspections

Ultrasonic testing in Egyptian pipeline inspections offers numerous benefits. It allows for non-destructive and accurate assessment of pipeline integrity, helping to identify potential flaws such as corrosion, cracks, and other defects. This method is also effective for inspecting pipelines in hard-to-reach areas, reducing the need for extensive excavation. Additionally, ultrasonic testing can aid in detecting defects early on, preventing costly and disruptive pipeline failures. Overall, implementing ultrasonic testing in pipeline inspections can enhance safety, reliability, and longevity of the Egyptian pipeline network.

Challenges and Solutions in Ultrasonic Testing for Pipeline Inspection in Egypt

gas ndt inspections service

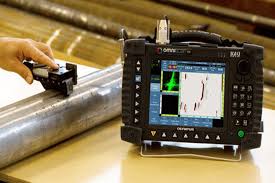

Challenges in ultrasonic testing for pipeline inspection in Egypt include the presence of coatings and insulation on the pipelines, which can hinder the accuracy and reliability of the test results. Additionally, the high temperatures and pressures in some pipeline systems can make it difficult to obtain accurate readings using ultrasonic testing methods. Solutions to these challenges include the use of advanced ultrasonic testing techniques such as phased array and time-of-flight diffraction, which can effectively penetrate through coatings and insulation to provide accurate inspection results. Additionally, specialized equipment and trained technicians can be employed to tackle the challenges posed by high temperatures and pressures in pipeline systems. Furthermore, the implementation of data management and analysis systems can help in interpreting the test results and identifying potential defects or areas of concern in the pipeline. Collaboration with international experts and organizations can also provide access to the latest technologies and best practices in ultrasonic testing for pipeline inspection.

The Role of Advanced Technology in Ultrasonic Pipeline Inspection in Egypt

Advanced technology plays a crucial role in ultrasonic pipeline inspection in Egypt. By utilizing state-of-the-art equipment and software, inspectors are able to accurately and efficiently assess the condition of pipelines, detect any defects or anomalies, and conduct thorough inspections even in challenging environments. Advanced technology also enables data collection and analysis, allowing for the generation of comprehensive reports and the implementation of targeted maintenance and repair efforts. This ultimately contributes to the safety, reliability, and longevity of Egypt's pipeline infrastructure.

Improving Pipeline Safety in Egypt Through Ultrasonic Testing

Improving Pipeline Safety in Egypt Through Ultrasonic Testing involves the use of advanced ultrasonic technology to inspect and detect any defects or weaknesses in pipeline infrastructure. This process helps to identify potential areas of concern and assess the integrity of the pipelines, ultimately contributing to the overall safety and reliability of the system. By leveraging ultrasonic testing, operators can proactively address issues and mitigate the risk of potential failures, ultimately ensuring the continued safe operation of the pipeline network. This is a crucial component of maintaining infrastructure safety and preventing potential environmental and public health hazards.

Best Practices for Effective Ultrasonic Testing in Egyptian Pipeline Inspections

The best practices for effective ultrasonic testing in Egyptian pipeline inspections include: - Proper training and certification of personnel carrying out the inspections to ensure accurate and reliable results. - Regular calibration and maintenance of ultrasonic testing equipment to ensure its effectiveness and accuracy. - Adherence to international standards and best practices for ultrasonic testing to maintain consistency and reliability in the inspection process. - Thorough examination of the pipeline surface to identify any defects or anomalies that may affect its integrity. - Proper interpretation of ultrasonic testing results to accurately assess the condition of the pipeline and make informed decisions regarding maintenance or repair needs. - Collaboration with experienced and reputable inspection companies with a track record of successful pipeline inspections using ultrasonic testing techniques.

The Future of Ultrasonic Testing for Pipeline Inspection in Egypt

Ultrasonic Testing (UT) for pipeline inspection in Egypt is expected to undergo significant advancements in the coming years. The technology is already widely used for detecting and characterizing defects in pipelines, but ongoing research and development efforts are aimed at enhancing its capabilities. One area of development is the utilization of advanced UT techniques, such as phased array UT and guided wave UT, which offer improved detection and sizing of defects in pipelines. These techniques are especially valuable for inspecting pipeline components that are difficult to access, such as welds and areas near bends or fittings. Additionally, there is a growing focus on integrating UT with other non-destructive testing methods, such as magnetic flux leakage and eddy current testing, to provide a more comprehensive assessment of pipeline integrity. The adoption of automated UT systems is also anticipated to increase in Egypt, reducing the reliance on manual inspections and improving the efficiency and accuracy of pipeline testing. Overall, the future of UT for pipeline inspection in Egypt looks promising, with continued advancements in technology and methodology enhancing the capability to ensure the safety and reliability of the country's pipeline infrastructure.